Multi Zone Process Temperature Control via a Single Interface

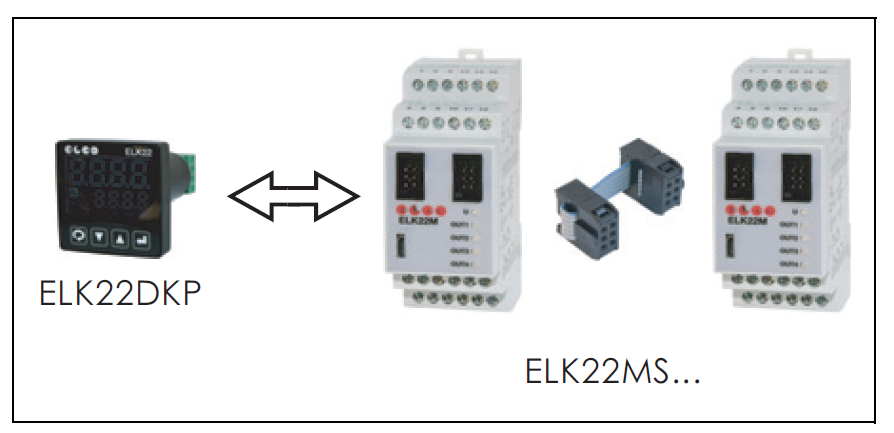

Up to 16 ELCO ELK22MS temperature controllers can be set up and controlled through a single ELK22DKP panel mount user interface and display.

The ELCO ELK22MS is a blind low-profile DIN rail mounted temperature controller.

The ELK22DKP panel mount user interface and display can be mounted through a 22mm hole, or a 45mm square cutout.

The controller functions can be either ON/OFF or PID control.

The following video includes an excellent overview of the concept:

Typical Applications for Multi Zone Temperature Process Controllers

It is common for an oven with a conveyor belt to require control of multiple temperature zones.

For example, automated bread ovens will lose more heat at the intake and outtake areas. This means more power may be required in these areas to maintain an even temperature along the baking area.

Another example is a curing oven at a brick factory, where it may take as long as a week for the bricks to pass through. Different heat and humidity profiles are required throughout the curing process to ensure a quality brick comes out at the end. If it cures too quicky it can crack, and if too slowly it will not be properly cured.

The process used in the production of sheet glass or hardening is much the same. If the temperature profile of heating and cooling is not followed proportionately to the speed of the conveyor, the glass will break or deform.

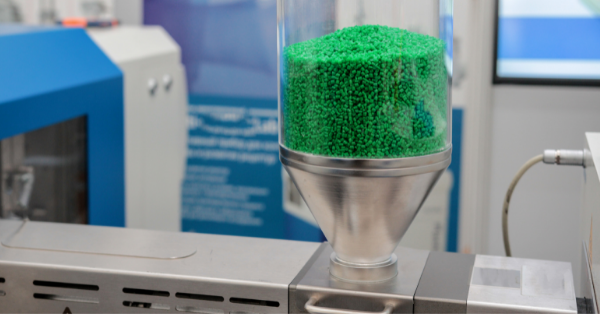

Another good example is the heating of the barrel on a plastics extruder. When the extruder first starts up, the hardened plastic in the barrel from the previous production run cannot flow and is susceptible to burning. This needs to be re-melted under controlled conditions. Once that plastic is flowing other pellets enter the barrel, where the temperature is adjusted to the optimum level required for them to melt and maintain the required product flow rate.

Advantages of Multi Zone Temperature Process Controllers

Typically, in these applications a single temperature controller is used to control each zone. Each of which has its own display and interface.

This can make for a difficult and costly panel build.

With the ELCO ELK22MS controllers you can control and monitor up to 16 controllers through one display / user interface.

Users can easily scroll between the ELK22MS DIN mount controllers as required.

The display / interface can also be password protected, preventing any unwanted tampering that could cause serious machine damage, loss of production, or injury.

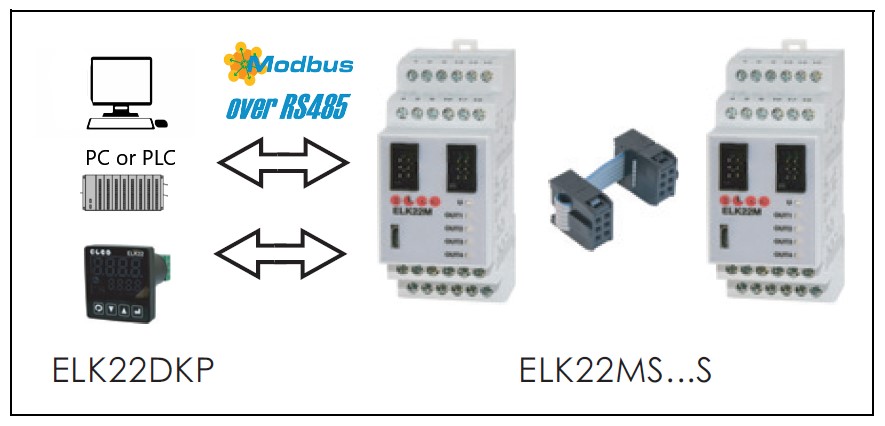

The Modbus RTU enabled models allow all setup and display readouts to be done via a PLC or HMI.

Managing Multiple PID Temperature Control Loops

Managing multiple PID temperature control loops in a PLC can be expensive.

Using independent PID temperature controllers can be advantageous, not only in terms of cost but also regarding CPU processing capability, especially if you are controlling multiple temperature zones.

Analogue inputs on PLC’s are expensive, a CPU with high processing power is often required to manage multiple PID loops.

The ELCO ELK22MS controllers are a simple and cost-effective method of managing multiple PID temperature control loops.

For further information, please contact ADM Instrument Engineering.

IS THIS INFORMATION USEFUL?

If so, why not share it with your peers and colleagues. Simply click on the blue LinkedIn share icon below.