IECEX Pressure Transducers for Hazardous Areas

The IEC (International Electrotechnical Commission) classifies hazardous areas into various Zones.

Explosive Gases

|

Zone |

Definition |

|---|---|

|

Zone 0 |

An area in which an explosive atmosphere is present continuously for long periods of time or will frequently occur. |

|

Zone 1 |

An area in which an explosive atmosphere is likely to occur occasionally in normal operation. It may exist because of repair, maintenance operations, or leakage. |

|

Zone 2 |

A place in which an explosive atmosphere is not likely to occur in normal operation but, if it does occur, will persist for a short period only. These areas only become hazardous in case of an accident or some unusual operating condition. |

Explosive Dusts

|

Zone |

Definition |

|---|---|

|

Zone 20 |

A place in which an explosive atmosphere, in the form of a cloud of combustible dust in air, is present continuously, or for long periods or frequently for short periods. For example, a mill or pneumatic conveying system. |

|

Zone 21 |

A place in which an explosive atmosphere, in the form of a cloud of combustible dust in air, is likely to occur occasionally in normal operation. For example, bagging points and inspection ports that are frequently opened. |

|

Zone 22 |

A place in which an explosive atmosphere, in the form of a cloud of combustible dust in air, is not likely to occur in normal operation but, if it does occur, will persist for a short period only. For example, leaks from incorrectly fitted lids or spillages. |

Safety in these hazardous areas can be achieved by two methods:

Intrinsic Safety (IS): EX ia

An intrinsically safe system is one where the design of the electronics and electrical circuits ensure energy levels are so low that they cannot cause a spark that would trigger an explosion.

This requires IECEx certified pressure sensors, which need a safety barrier circuit.

Explosion Proof: (Ex d)

This type of protection is achieved by the physical design of the pressure sensor’s enclosure and the installation wiring and hardware

The idea is that any flame or spark is contained, separating it from the explosive atmosphere outside.

Cost Comparison of Intrinsic Safety and Explosion Proof Pressure Measurement Systems

Ex d rated pressure transducers can cost more than intrinsically safe pressure sensors.

However, the overall cost depends on the application itself.

Explosion proof wiring is much more expensive to install than intrinsically safe wiring, because it requires explosion proof conduit and seals to isolate the circuit from the hazardous environment. Therefore, if long cable runs are involved, an intrinsically safe installation may be more cost effective. This is because the cost of the safety barrier required in an intrinsically safe installation could be cheaper than buying a considerable amount of conduit.

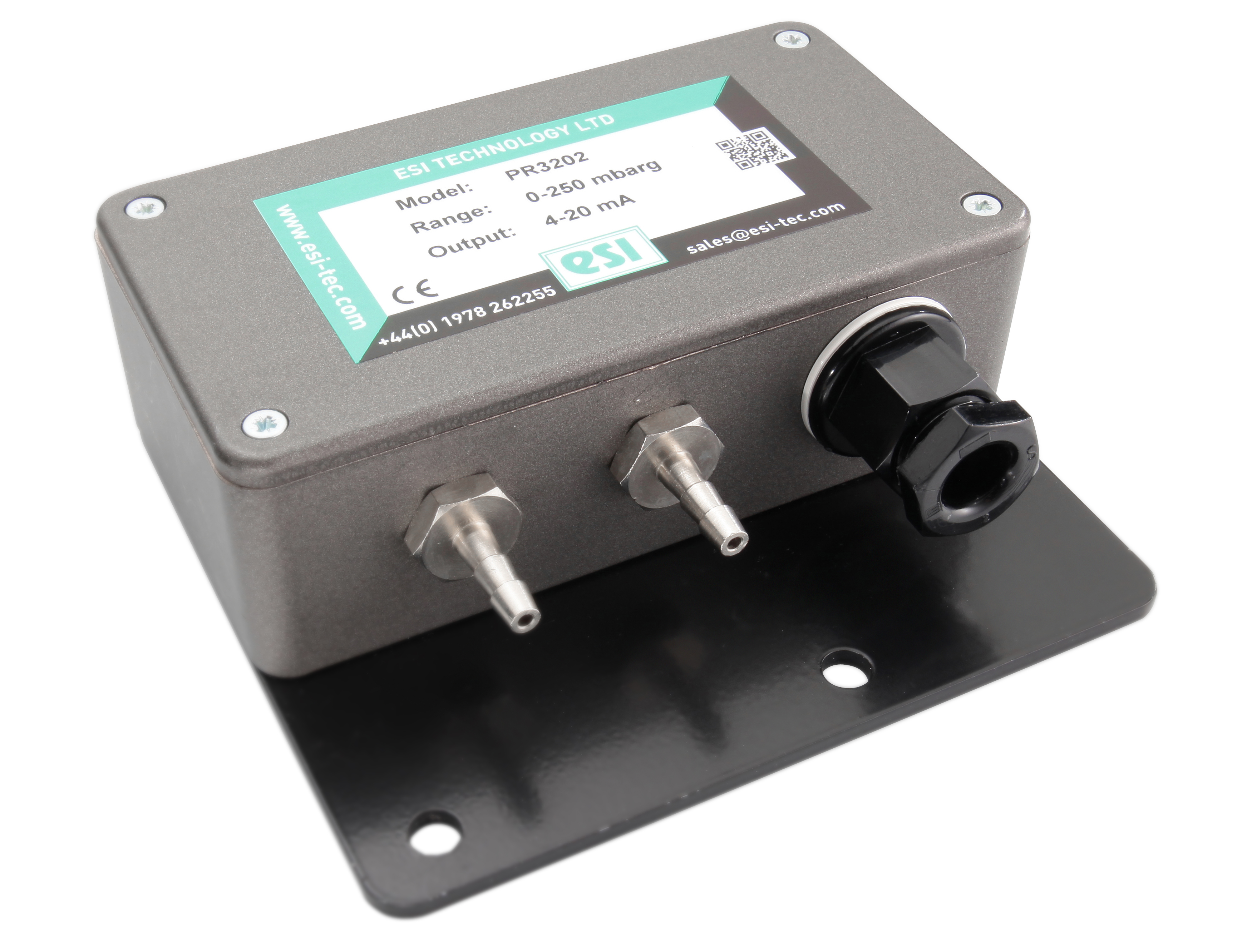

IECEx Pressure Transducers

Many of ESI Technology’s range of pressure transmitters have the option of being ordered with IECEx certification, which allows them to be used in Intrinsic Safety applications.

Not only are ESI’s pressure sensing devices safe to use in explosive environments, they are also manufactured according to the highest international standards of safety.

ESI are also developing a range of explosion proof pressure sensors that will have Ex d approval for those who prefer to achieve safety with this method. ADM will make further announcements about these products, once they are available.

The following ESI pressure transducers can be ordered from ADM with an IECEx certificate:

|

Series / Link |

Description |

|

|---|---|---|

|

Silicon on saphire technology |

|

|

|

HI2000 |

High precision pressure transducer |  |

| High pressure measurements |  |

|

|

PR3100 |

Standard barrel type |  |

| Differential pressure transducer |  |

|

| Differential pressure transducer |  |

|

|

PR3420 |

Submersible Pressure transducer |  |

| Hydrostatic Level Sensor |  |

|

|

PR3800 |

Flush Diaphragm Pressure Transducer |  |

| Flush Diaphragm Pressure Transducer |  |

|

|

PR3860 |

High Temperature Pressure Transducer |  |

|

PR3900 |

Hazardous Area Pressure Transmitter |  |

|

PR3913 |

Subsea Pressure Transmitter |  |

|

PR3915 |

Dual Redundant Subsea |  |

|

PR3920 |

Subsea Pressure Transmitter |  |

If you would like further information on pressure transducers for hazardous areas, please contact ADM Instrument Engineering.

WAS THIS INFORMATION USEFUL?

Why not share it with you industry peers on LinkedIn? Simply click on the blue LinkedIn share icon below.