What is the Best Type of Linear Position Sensor to Use?

There are several types of linear position sensor available, many of which are stocked by ADM.

One question we are frequently asked is what is the best type of linear position to use?

The answer is it very much depends on your application.

Where some people can be confused is determining the difference between linear potentiometers and LVDT transducers.

What are the Differences Between LVDTs and Linear Potentiometers?

Linear Potentiometers and LVDTs (linear variable differential transformers) have several features in common, which makes it a little unclear as to which applications each is best suited to.

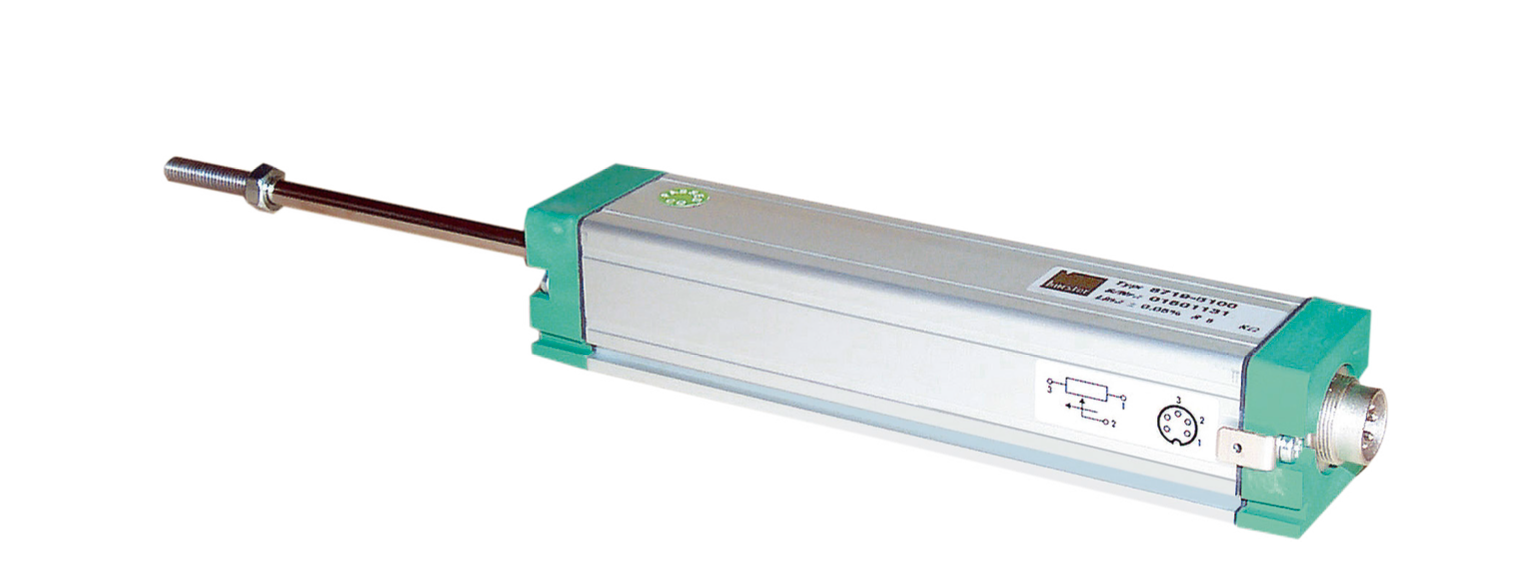

Both the linear potentiometer and LVDT, measure the physical displacement of travel of an object and provide an electronic control signal of that information. The physical design of a linear pot and LVDT consists of a solid shaft that moves in and out of a tubular or rectangular housing.

Options, such as a spring return action is possible with either.

Linear PotentiometerS

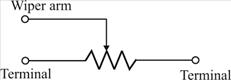

The electronic symbol of a linear potentiometer explains a lot about this sensor.

The linear potentiometer has a wiper arm that slides along the surface of a resistor.

The resistor has a fixed value between the two end terminals. However, the resistance will vary according to the distance between a terminal and the wiper arm’s position as it travels along the resistor.

The resistor could be one of several types such as wire-wound, graphite, and more lately conductive plastic.

Linear potentiometers are far more cost effective than LVDTs. However, you do need to check the data sheet to ensure that the life cycle of the linear potentiometer is adequate for your application.

Good quality linear potentiometers that utilise conductive plastics, smooth surfaces and other design features to reduce the friction between the wiper and the resistor surface, will typically last for millions of cycles.

However, the ingress of dirt or moisture can only shorten the life span.

This means linear potentiometers are perfectly OK for applications such as monitoring the position of a guide arm on a conveyor belt. However, they are not suitable for monitoring high speed and highly repetitive motions. This is where the LVDTs come in.

You will find linear potentiometers in industrial automation processes and machinery, as well as automotive and mobile moving machinery.

ADM Instrument engineering offers a good selection of linear potentiometers with different designs, travel lengths, physical sizes and ingress protection ratings.

LDVT Linear Position Transducers

LVDT technology has the advantage of avoiding the main issue of wear and tear associated with linear potentiometers.

As the moving shaft retracts into the LVDT’s housing, the shaft acts as the core of a transformer and the more it moves in, the more it allows that energy from the primary coil to induct into the secondary coil. The amount of energy inducted into the secondary coil, is directly proportional to the distance the shaft has travelled in or out of the housing and its electromagnetic field.

An LVDT is considered a contactless means of measurement. Certain designs are even suitable for complete submersion, with the chamber being flooded with water

LVDTs are found in laboratory & research applications, as well as in aerospace, military and automation tasks.

LVDTS are also suited for measuring high speed repetitive cycles and can be expected to endure in harsh environments. Some LVDTs are supplied with integral electronics to convert the output signal into a more commonly accepted control signal, such as 4-20mA or 0-10V

ADM offers a comprehensive range of LVDTs.

Further Information and Assistance

If you would like assistance in selecting a suitable linear position sensor, please do not hesitate to contact ADM Instrument Engineering.

IS THIS INFORMATION USEFUL?

If so, why not share it with your peers and colleagues. Simply click on the blue LinkedIn share icon below.