Hydrostatic Pressure Level Measurement in Food & Beverage Production

Having an accurate level measurement of your raw liquid materials is an integral factor of food & beverage production. In this article, we look at a customer case of a hydrostatic pressure sensor used for a bottled water supplier.

The ADM Sense Team assisted a customer, who supplies high-quality spring water from an underground bore to a popular Australian bottled-water brand. ADM’s customer faces some unique challenges in sourcing the water, not only in terms of resource management. Given the operation's geography, the supplier must adhere to regulations that preserve the regional water table. These regulations are in place for the prevention of any potentially major ecological and geographical problems in the region.

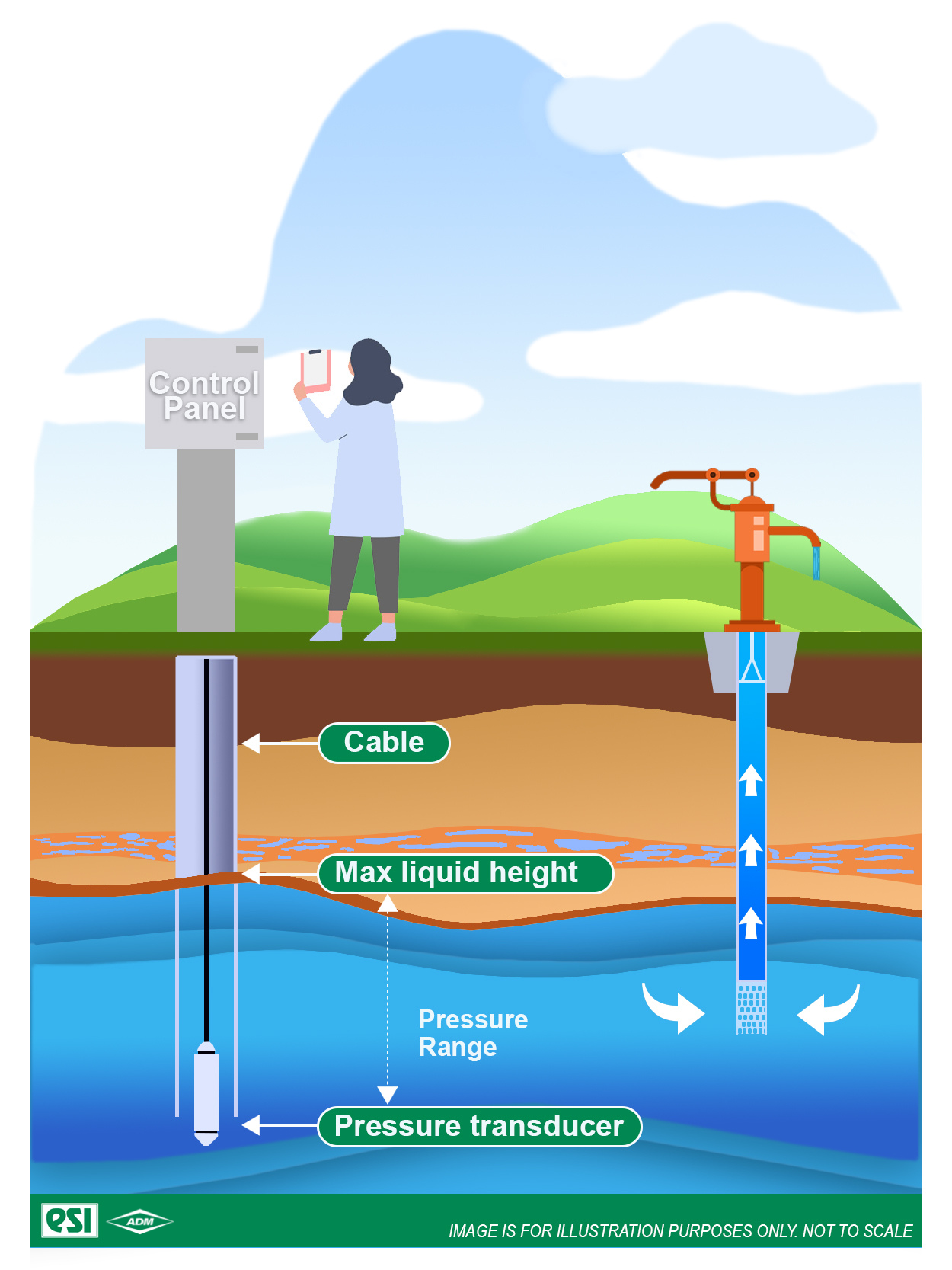

To address these challenges, the installation of the hydrostatic level sensor and a recording device on each well's bore allows for the correct management of the customer’s operations.

The hydrostatic pressure sensor is an instrument that can be deployed on almost any open vessel to check the level of liquid within. This system is easily deployed by placing the hydrostatic pressure sensor at the bottom of the vessel. The sensor is subjected to the liquid's pressure, and as such, produces a signal. With consideration for the liquid density or specific gravity (SG) of the liquid within, the pressure applied to the sensor output signal is directly proportional to the depth of the liquid within the vessel or down the borehole.

Because the water is for human consumption, care needs to be taken when selecting the sensor’s cabling material that contacts the water. This is important as bacteria, microbes, and trace elements of plastics from lesser-quality cabling can contaminate your water.

If you are selecting a hydrostatic level sensor for food and beverage production, ensure your sensor has food-grade polyurethane cabling, to prevent damage and contamination to the water source.

If you are looking for some guidance on employing a hydrostatic liquid level measurement sensor within your food & beverage production,

The ADM Engineering team is ready to help! Contact us here.