Measuring Brix: Inline Process Refractometers and High-Quality Sugar Production

This article delves into Vaisala Inline Process Refractometers improving and maintaining sugar quality and consistency with constant monitoring of brix levels within the various phases of Sugar milling and Sugar refining production.

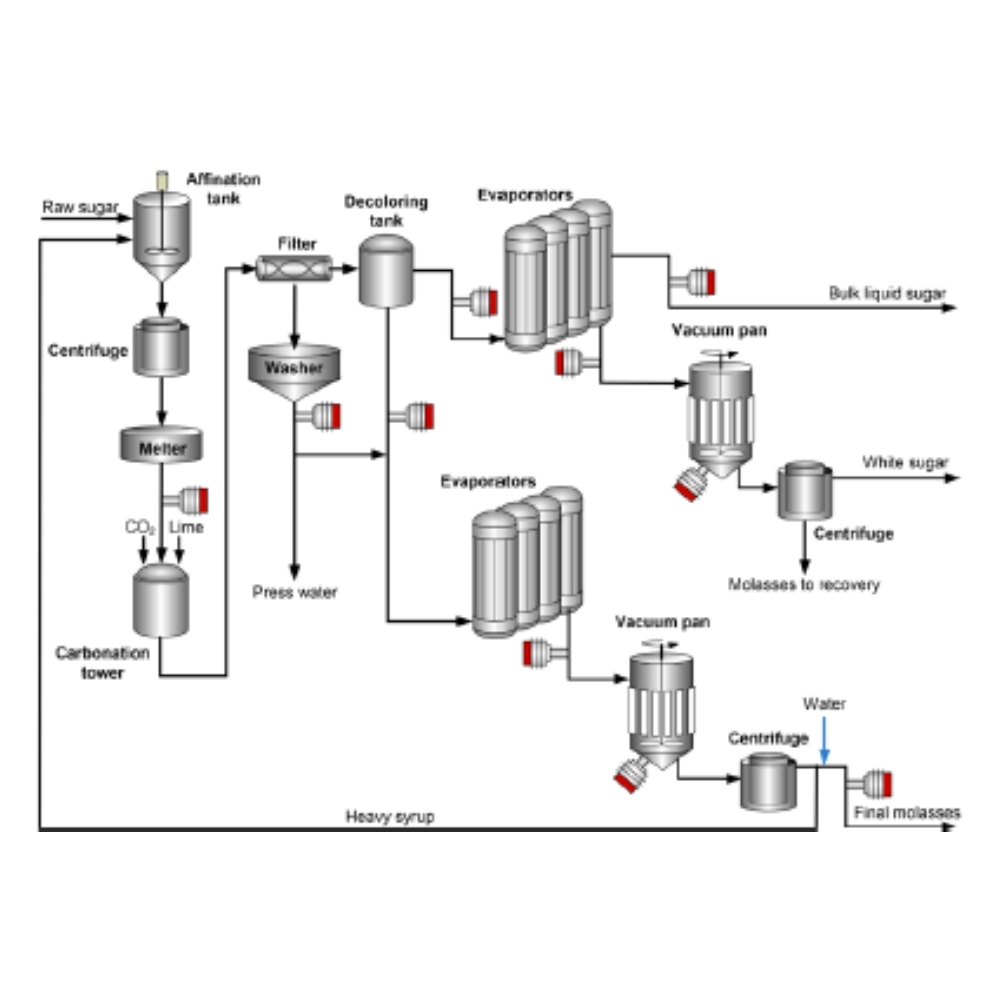

Sugar production is an around-the-clock process, from milling to refining, raw materials are time sensitive for processing to ensure a high-quality product. Consistent accurate measurement of Brix liquid concentration throughout the process, particularly in the crystallization phase can greatly support achieving the goal of producing consistent and even-quality sugar crystals, avoiding undesirable fines and conglomerates requiring remelting, thus creating resource efficiencies from energy and water, increasing production yield.

BRIX: Continuous Monitoring of Liquid Concentration

The Vaisala K-Patents and Polaris inline Process Refractometers are the answer to the continuous and consistent measurement of Brix in aqueous solutions. These instruments are installed in-line in the production process, directly mounted in pipes and vessels in both compact and probe styles.

Automatic washing with hot water or steam ensures the prism is kept clean for maximum accuracy of measurement.

Colour, Bubbles, Particles, Flow and Temperature.

Vaisala K-PATENTS® and Polaris Inline Process Refractometers are unaffected by colour, bubbles and solid particles in the media. Every refractometer is fitted with a temperature sensor for compensation of process temperature, therefore making them ideally suited for measurement of Brix in Magma, Mother Liquor, Massecuite and Molasses.

How does a refractometer work?

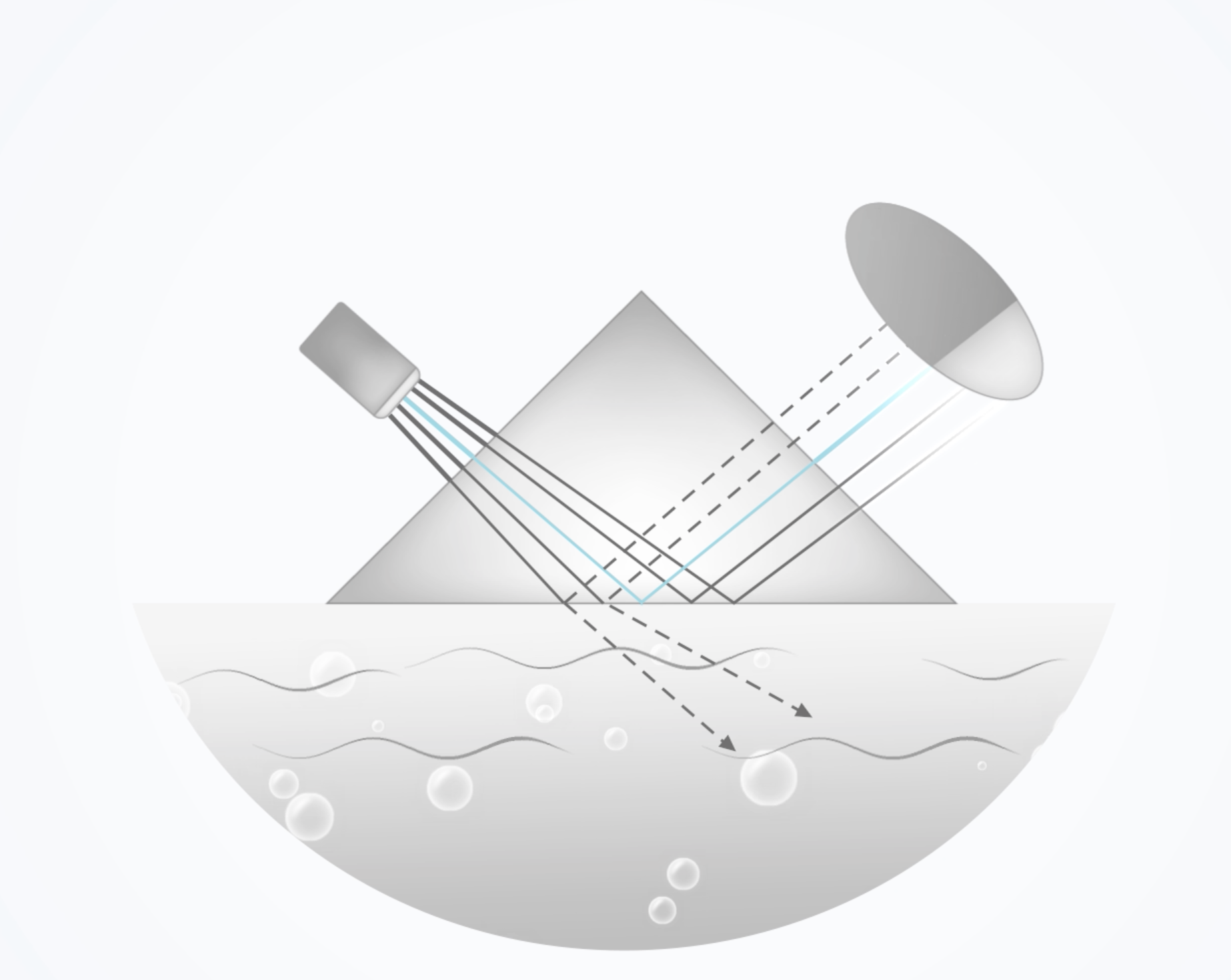

The Vaisala K-PATENTS® and Polaris Inline Process Refractometer consist of three modules, a light source, a prism, and a digital image processor, all of which are encased within a stainless-steel body that is in direct contact with the process media.

To produce a measurement, the light is directed through the prism, which depending on the concentration of liquid, will refract into the liquid and reflect all remaining light into the digital image processor to measure the Refractive Index of the liquid. This principle of measurement is called "The Critical Angle of Measurement" and provides a highly accurate and repeatable measurement of liquid concentration. Both analogue and digital outputs are available to interface with control systems for continuous measurement.

How does a refractometer fit into my application?

Various stages of the sugar manufacturing process may introduce different-sized pipes or vessels. For this purpose, the Vaisala K-Patents and Polaris Inline Process Refractometer sensors can be supplied in probe style for flange mounting in vessels and pans, or compact style for in-line pipe mounting.

Would you like to know more?

Learn more about how to increase efficiency and profits by using the Vaisala K-Patents and Polaris range within your Sugar factory by getting in touch with the ADM Sense Team today!