Controlling the Chocolate Manufacturing Process

Producing chocolate involves several process stages, in which the chocolate must be maintained in a liquid state up until the final stage, when the chocolate is ‘tempered’ into a solid state.Conching and tempering are two important phases, and the quality of the final product depends on precisely controlling these two processes.

Conching

Conching is a process where a surface scraping mixer and agitator, known as a conche, evenly distributes cocoa butter within the chocolate.

It also promotes flavor development through frictional heat, release of volatiles and acids, and oxidation.

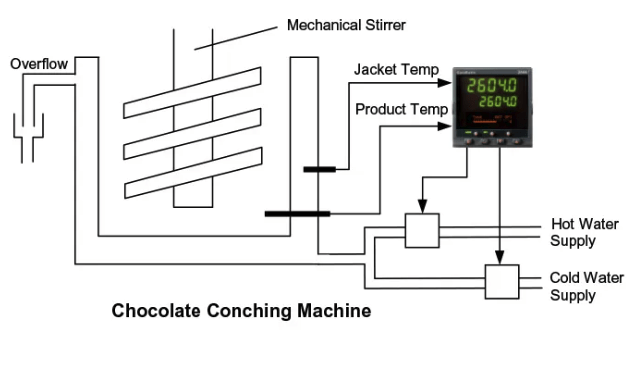

A chocolate conching machine consists of a vessel with a double wall, which enables circulation of the warm and cool water, and a series of mechanisms which create continuous grinding and mixing movements.

Precision control is required as conching changes the taste, fineness, and homogenisation of the chocolate. The chocolate also needs to remain in a liquid state during the process.

Controlling the Conching Process

Because of the long delay in the heating and cooling cycles, normal single loop temperature controllers tend not to work well with this type of system, leading to a degradation in the quality of the end product.

The Eurotherm 2604 or Nanodac are ideal for this application.

This is because a cascade control can be set up.

The heating and cooling are controlled by pulsing solenoids. These allow hot and cold water to flow into the conch’s jacket.

Using the cascade PV feedforward option that is available in the Eurotherm 2604 & Nanodac, it is possible to limit the temperature difference between the water jacket and the chocolate. This is particularly desirable when cooling to ensure that any chocolate close to the wall of the jacket does not solidify while the bulk of the chocolate is still warm.

The Nanodac can also record the process data securely, for quality control and any regulatory compliance requirements.

Please do not hesitate to contact ADM, if you would like assistance in selecting a suitable process controller for a process which requires the accurate control of temperature.