Pressure Switches for Industrial Water Pump Control

This blog post discusses how pressure switches, digital pressure gauges, and pressure transmitters are used to control pumps in industrial applications. Pipeline pressure is often controlled by a simple water pressure management system.

There are many basic all-in-one pump controllers that make for a quite easy installation.

However, there is a limit to the size system that these can support, typically around 1.5kW pump motor, so they are not always suitable for industrial applications.

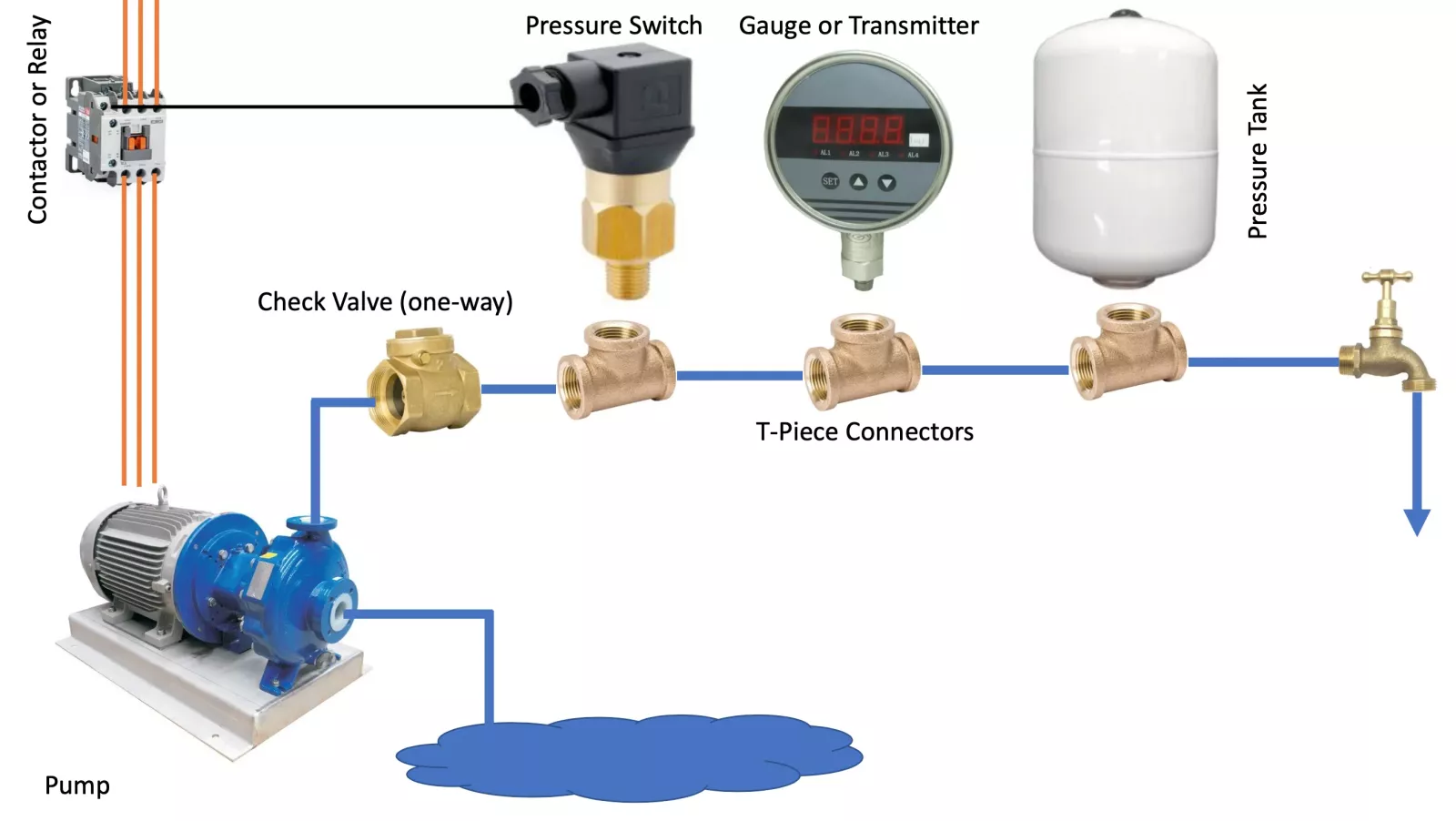

A water pump control system built as a modular system is the preferred approach in industrial applications, using the following components:

- Pressure switch

- T-piece connectors

- Contactor or relay

- Pressure gauge (or transmitter)

- Check valve, (one-way flow)

- Pressure tank (or long pipeline)

The pressure switch is mounted in line with the flow output of the water pump using a T-piece connector so that the water can flow past as the pressure is being monitored.

Some applications require a digital pressure gauge for a local readout of the pressure, or a pressure transmitter for feedback to a remote display, PLC, or other control system.

A pressure tank is often used to help regulate the pressure in the line and ensure that there is water ready to flow when required. The pump will only turn on when the pressure tank pressure gets down to the threshold.

The pressure tank acts as a buffer. For example, when a tap or valve is opened, water is available to flow from the pressure tank instantly, and there is no delay from the pump starting the flow. The pressure switch also has one set point with some hysteresis, so that the pump does not start and stop with the smallest changes in pressure.

When the line pressure falls below the lower limit the pressure switch output will close and stay closed until the upper pressure limit is reached, after which time the pressure switch will open.

In some installations, the piping network may be long enough to act as a pressure tank.

The check valve is a one-way device that prevents water from flowing back through the pump once it stops.

The contact in the pressure switch is only rated for 5amps at 250AC maximum, and is not suitable to switch most pumps directly, which is why an external relay or even contactor is needed for higher power or to switch 3-phase pump motors on and off.

This type of system described above can be used to maintain pressure in pipelines or systems that are run by large 3-phase motor drive pumps.

ADM stocks a wide range of pressure switches, digital pressure gauges, and pressure transmitters that can be used in such applications.

If you need assistance in selecting a suitable pressure switch, please do not hesitate to contact ADM Systems.