Understanding the Safe Torque Off Feature of Invertek’s Optidrive P2 VSD

To facilitate understanding of the Safe Torque Off (STO) feature of the Invertek Optidrive Variable Speed Drive P2 (VSD), let us first understand what torque is. Torque is the measurement of applied force that causes an object to twist or rotate. It is commonly measured by Newton-meters (Nm) or pound-feet (lb-ft).

Torque is a key factor in gauging how objects execute rotational tasks in many applications within the automotive, engineering, manufacturing, and research industries.

The STO function of the Invertek Optidrive P2 Variable Speed Drive is a precautionary function used to stop an inverter drive from creating torque in a motor by cutting off power to the motor's output. This ensures that the motor will not start unexpectedly or store rotational force — making it an important safety control systems feature. The STO is built into Invertek VSD P2 models through dedicated input terminals.

If you have a project that requires this safety feature, contact ADM for technical advice, we can help.

What are the Safety Standards of Invertek Optidrive P2 VSD?

Invertek Optidrive P2 VSD models meet the following safety standards in preventing unintended motor operation.

IEC 61800-5-2 (Functional Safety of Variable Speed Drives) – STO is classified as a Type 2 safety function

Meets Safety Integrity Level (SIL) 2

What Does the STO Function Cover?

The STO mainly disables the torque producing power from the motor output while the power to the drive control circuits is maintained.

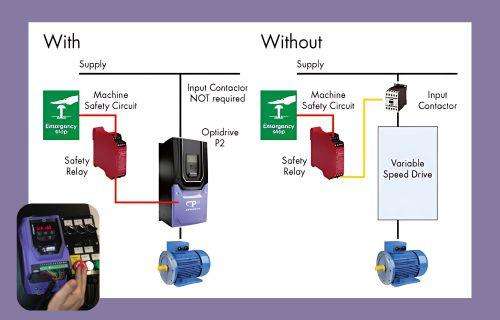

What this means is that, when STO is engaged, the motor will not generate torque, and will come to a smooth coast rather than an abrupt stop. The STO also eliminates the need for external contractors, which simplifies the safety system.

It is important to note, however, that even if STO is engaged, proper insulation must be provided before carrying out maintenance, as it does not remove high voltages from the drive input terminals.

How do you Monitor the STO Function Status?

The STO function's status can be monitored through different methods:

Drive Display: An “Inhibit” message will be displayed when the STO is activated.

Drive output relays: The relay outputs (P2-15 or P2-18) can be linked to the status of the STO function. If either of them is set to a value of “13”, this will cause the STO function to be activated.

Fault Codes: The drive will display an STO-fault related error, such as “Sto-F” fault 29, if an internal STO fault is detected.

Installation Considerations for STO

It is crucial to keep the following in check when integrating the STO function into a system:

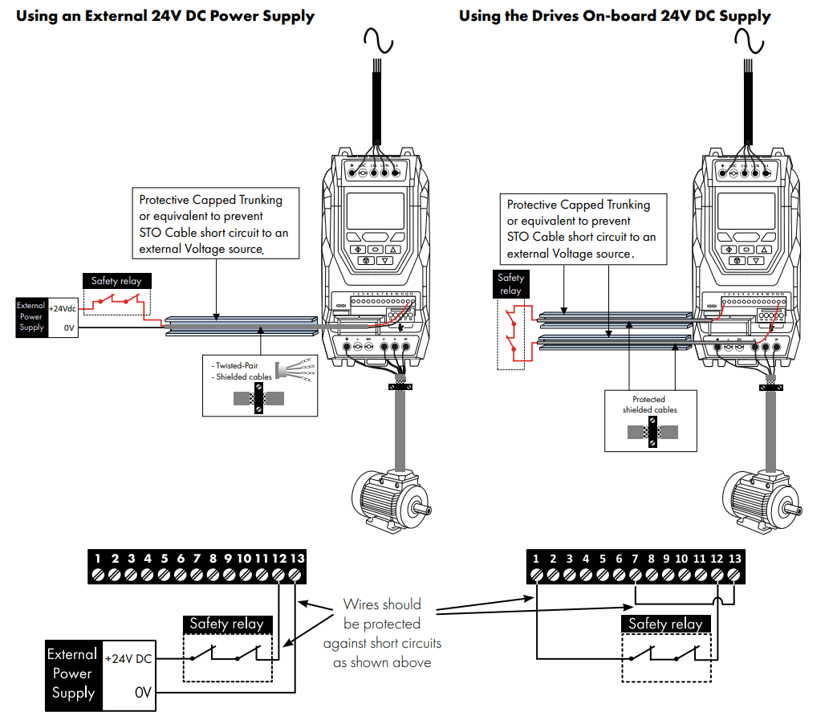

Use only properly shielded and protected cables to avoid unintended short circuits or interference.

Ensure that the STO wiring is correctly done according to the recommended 24V DC signal source. This can be derived from the drive itself or from an external power supply.

Maintain a maximum of 25m cable length between the voltage source and drive terminals to prevent signal deterioration.

Use relays that meet a minimum of SIL 2 standards with forced guided contact. This ensures compliance with safety regulations.

Enabling and Testing the STO Function

Although the STO function is built into and enabled on the drive, it still requires testing before commissioning.

Follow these steps to test the STO function of your VSD.

Motor at Standstill:

The STO inputs needs to be de-energised, this means that the display should show “Inhibit.”

When a start command is issued, the motor should not start.

Motor Running:

The STO inputs are de-energised while the motor is operating.

The motor seizes immediately, and the display reads “Inhibit.”

Fault Reset:

While carrying out the test procedures, if it the drive detects an STO fault, the drive needs to be reset and the STO inputs re-energised to resume normal operation.

How to Maintain the STO Function

To ensure the STO function's long-term reliability and safety, regular maintenance is recommended.

You can do this by testing the STO function regularly, by checking the system wiring for any wear or damage, confirming that software parameters are correctly set, and ensuring that the drive's rated limits fit within its environmental conditions.

Do you need more information or technical assistance? Contact our Invertek VSD experts here.