Variable Speed Drives & PID Loop Control in the Blown Film Process

Blown film is an industrial process that converts molten polyethylene into a plastic film. The plastic film product can then be fashioned to create a range of plastic bag products. A key quality factor in the blown film process is the constant monitoring and control of the cooling rate throughout production.

Making a blown film bubble

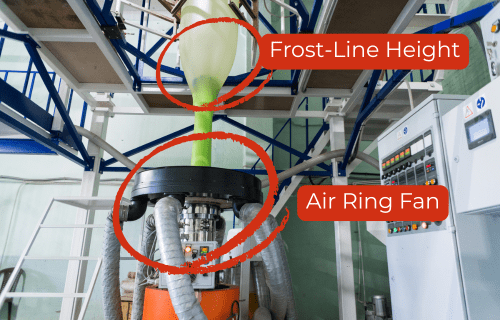

The blown film process is similar to that of blowing a soap bubble. Molten polyethylene is extruded and stretched across a ring, blowing air into it to inflate the molten polyethylene in a similar way to that of a bubble. This process is encompassed in a broader ring of blowing air, appropriately named an air ring.

The air ring is tasked with cooling and stabilising the polyethylene bubble to reach the frost line height, solidifying the polymer in a rigid film as it is fed/floats upwards to be captured and rolled by the nip rollers.

Controlling the conditions

Optimised conditions rely heavily on monitoring the film temperature at the frost line. If the film is too warm or too cool and doesn’t meet the desired frost-line height set point, the system's sensors can relay this feedback to the motor speed settings of the air ring fan, increasing or decreasing the speed as needed.

Eurotherm PID Loop Control & Invertek Speed Drives

To achieve this, the blown film process will exist as a part of a much larger PLC system; however, for this distinct section of the process, it would entail the integration of a PID loop controller, such as the Eurotherm 3500 series, an infrared temperature sensor, and a variable speed drive, such as the Invertek Variable Speed Drives.

The 3500 series PID loop controller would be tasked with relaying live temperature readings from the infrared temperature sensors at the frost line height. The 3500 series PID loop controller would be determining if the temperature falls within the desired frost-line height setpoint range. If the live temperature exceeds or falls below the setpoint, the Eurotherm PID loop controller will send a signal to the Invertek variable-speed drive to increase or decrease the frequency of power, in turn increasing or decreasing the speed of the AC motor powering the air ring fan.

Suppose you’d like to learn more about how Eurother PID loop controllers can be integrated to work with Invertek Variable Speed Drives to better assist you in managing quality at the production level. In that case, the ADM system team is here to help!

Please send any questions through to our team via our contact page here or call the team directly on 1300 236 467.