Can Pressure Transducers Withstand Freezing Water?

During winter season in Australia, cold masses of air from a weakened and displaced polar vortex would sometimes stretch to the southeast regions of the country. This phenomenon can drastically reduce average temperatures, cause unpredictable rainfall, and in rare cases bring snow to areas not known to experience it.

Where industries use pressure transducers for agriculture, horticulture, and irrigation purposes in this region, it is important to know that the sensor inside the transducer compartment could rupture if subjected to water freezing within its chamber.

If you think that you may be affected by this situation, we recommend using pressure transducers and transmitters equipped with a flush diaphragm design, such as ESI’s PR3850 model, or contact ADM so we can recommend other suitable options.

How Does Freezing Water Damage Pressure Transducers?

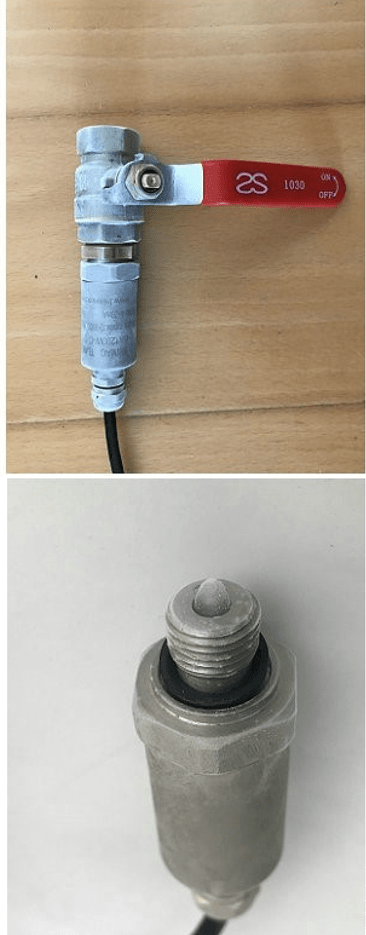

Inside a pressure transducer/transmitter is a small cavity or pressure passage that leads to the sensor. This pit could sometimes hold a small amount of water that if left at freezing temperatures, can cause the water inside to freeze, expand, and eventually cause enough pressure to rupture or deform the diaphragm permanently.

Pressure transducers with deformed or ruptured diaphragms leak fluid into the electronics, which render them unserviceable; hence, require replacement.

Pressure Sensor's Operating Temperature and Freezing Points of Various Liquids

Many engineers do not realise that a datasheet stating that a pressure transmitter is suited for, say minus 20°C (-20C) etc., does not equate to the device's capacity to withstand water freezing solid within the sensor chamber. The -20°C shown on specifications allows for many liquids including oils, alcohols and fuels that have lower freezing points than water, which freezes at 0°C. In most cases, this also allows for air and gases that reach below 0°C, so it is important to get a suitable sensor for the type of media it is intended for.

In areas where water freezing in pipes is possible, it is advisable to protect the pipes and instruments with insulation, such as foam sleeves and fabric wraps.

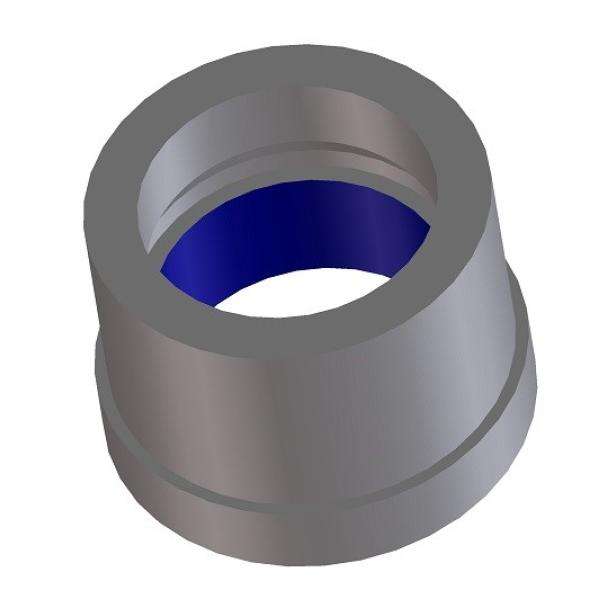

To maintain the integrity and proper working condition of pressure transducers and transmitters in areas subjected to freezing conditions, models with process connections that prevent fluid from passing through the sensor would also be suitable. An example of this would be the flush diaphragm type ESI PR3850 model.

Features of the ESI PR3850 - Flush Diaphragm Pressure Transducer

The ESI PR3850 model is made of stainless steel with a custom integrated circuit (IC) amplifier, and is particularly suitable for use with high viscosity materials or materials that have higher resistance to flow, like honey or slurry.

The flush diaphragm design is a smooth surface impenetrable by liquid, which makes it easier to clean and to maintain. The PR3850 model is mostly used in wastewater facilities, food production, pharmaceuticals, petrochemical, and other similar industries.

Economical Pressure Transducer for Agricultural Applications

The new freeze-resistant TSA-1202PT model compliments the TSA-1200PT standard series. This new model is great for agricultural applications, and is now available at ADM.

This new variant incorporates a wave-shaped spring as part of the sensor element, which makes it resilient to the effect of water solidifying in freezing points. Please contact our engineers for more information about TSA-1202PT, or if you would like to find out more about suitable pressure transducers for your application.