Comparison: Precision Potentiometer vs. Hall Effect Sensor

To measure linear displacement, a draw wire transducer is an ideal instrument for a multitude of applications, including suspension travel, valve position, forklift operation, scissor lift height, and steering position.

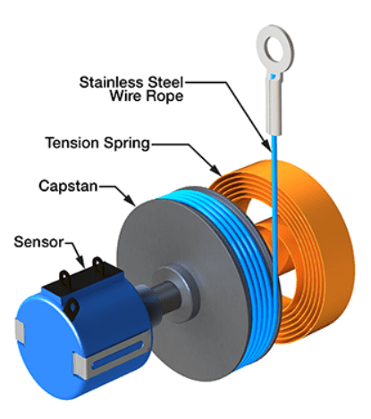

As the draw wire extends, it rotates an internal sensing device to produce an electrical output signal proportional to the position, whilst an internal torsion spring maintains tension on the wire rope and serves as the retraction mechanism. The figure below illustrates the key components of a draw wire sensor.

Two technologies used for sensing linear displacement are the multiturn precision potentiometer and a Hall effect sensor.

Precision Potentiometers

The precision potentiometer is a highly accurate variable resistor that provides a ratiometric output voltage proportional to the linear position. It is simple in design, draws very low current, and is made with robust materials that exhibit highly linear resistance characteristics. As they require a wiper that traverses the resistive material, they are susceptible to wear that induces output noise voltage.

Wear and dirt buildup will also affect wiper contact resistance, which in turn affects accuracy. Despite these minor drawbacks, potentiometer draw wire linear displacement sensors have a lifetime of several hundred thousand complete stroke cycles.

Hall Effect Potentiometers

Hall effect is the voltage that is produced across a conductive material, such as a semiconductor, when a current is flowing through it while subjected to the presence of a magnetic field. With a constant current flowing through the semiconductor and close to the magnetic field, the relationship between magnetic field strength and generated voltage is linear.

The non-contact aspect of the Hall effect provides a frictionless means to measure linear displacement, significantly enhancing product lifetime due to reduced wear and tear. This is particularly beneficial when the application experiences periods of dither, i.e., the draw wire is extended and held at specific positions on a vibrating machine, which would otherwise cause rapid wear in the case of a contact-type technology.

At ADM Systems, we've proudly supplied Unimeasure, a world-leading manufacturer of draw wire linear displacement sensors that cater to both precision potentiometers and Hall effect sensors. If you have a challenge that requires a potentiometer and can’t reasonably determine whether a precision potentiometer or a Hall Efect sensor is the right solution, call the ADM team today!

Please send any questions regarding your intended application to our contact page or call us directly on 1300 236 467.