The ADM Guide to Load Cell Technology – Selecting Load Cells & Support

Accurate weight and force measurement are integral components of industrial automation. These applications range from food processing to testing the breaking point of power poles or weighing trucks at a weigh station; the load cell is at the heart of these operations.

In this guide, we cover the force measurement ecosystem, from understanding the basics of load cells to supporting and accessorising with adequate cabling, displays, and support electronics, such as transmitters and summing boxes, to support complex weighing system integrations.

The Fundamentals of Force Measurement

What is a Load Cell?

In essence, a load cell is a transducer that converts energy from one form to another. More specifically, converting force such as tension, compression or torque into an electrical signal. Most industrial load cells use strain gauges arranged in a Wheatstone bridge configuration. As these are passive sensors, they will typically require an external excitation voltage to operate and return a signal measured in millivolts per volt (mV/V).

Common Types and Applications

Selecting the right form factor is the first step in system design. Load cells generally fall into specific categories based on how they receive force:

Compression & Tension (S-Type): Named for their shape, S-Type cells are versatile. They are ideal for hanging scales or measuring force on rail couplings. They are self-aligning when used under tension, which helps minimise errors caused by side loads.

View our range of S-Type Load Cells here.

- Compression Only:

Shear Beam Load Cells: The industry standard for floor scales, tanks, and conveyor belts. They are robust and often used in sets of four under a platform.

View our range of Shear Beam Load Cells here.

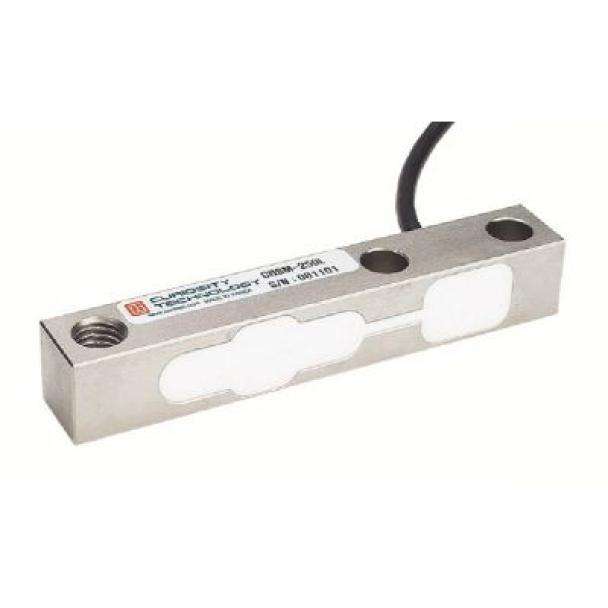

Single Point Load Cells: These features have a unique internal structure that allows them to measure weight accurately even if the load is off-centre. They are perfect for smaller scales in the food or medical industries.

View our range of Single Point Load Cells here.

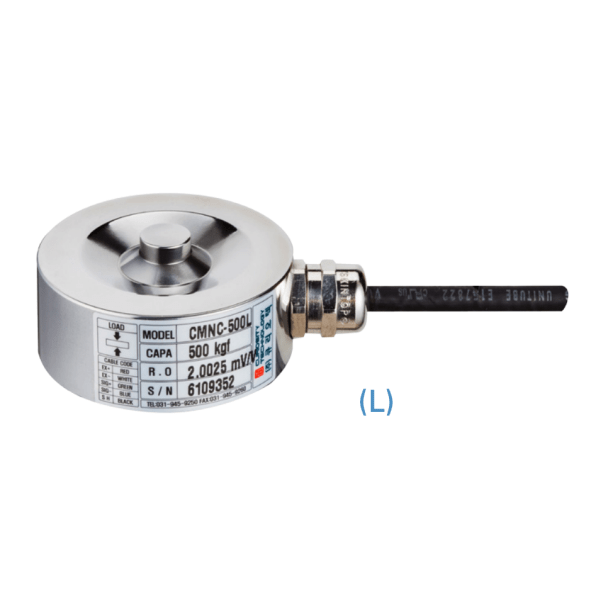

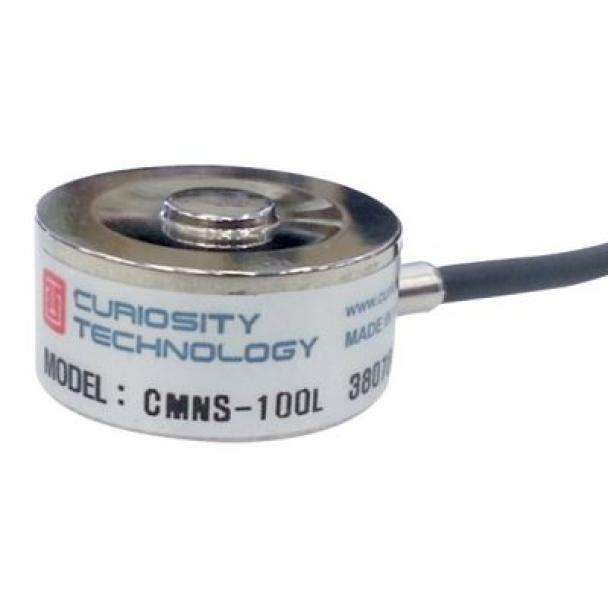

Miniature/Button Load Cells: Designed for tight spaces where mounting hardware is impossible to fit, often used for retrofitting machinery.

View our range of Miniature Load Cells here.

Canister (Column) Load Cells: Built for high-capacity jobs like weighbridges and truck scales. Their cylindrical shape withstands immense vertical pressure while resisting environmental factors such as moisture.

View our range of Pancake & Canister Load Cells here.

- Specialised Load Cells: For niche applications, Anchor Load Cells are used to monitor tension in dams and bridges, while Hygienic Load Cells are designed to meet sanitary standards for food and pharmaceutical production.

Unsure which specific shape fits your machine?

- Read: What type of Load Cell should I use?

- Read: CURIOTEC Load Cells for Force and Weight Measurements

Load Cell Selection and Accuracy

Interpreting the Data Sheet

Accuracy is not just a single number; it is a combination of factors. Data sheets often list accuracy as %RO (Per cent of Rated Output). For example, a 1000kg load cell with an error of ±0.5% RO effectively has a resolution of ±5kg.

However, real-world conditions differ from the lab. You must consider:

- Temperature Effects: Heat can cause the "zero" point to drift or alter the output value. High-quality cells have temperature compensation ranges (e.g., -10 to 40 °C).

- Creep: If a load is left on a scale for a long time, the signal may slightly change (drift) even if the weight hasn't changed. This is known as creep.

Avoiding Common Pitfalls

One of the most frequent issues arises when replacing a load cell without consulting experts. A cell might look identical to the old one but have a different sensitivity or wiring configuration. Critical factors often overlooked include the direction of force, the mechanical dimensions, and whether the material (stainless steel vs. aluminium) is suitable for the environment.

Need a little more? Read these blogs;

- Read: Determining Load Cell Accuracy

- Read Load Cells: Common Problems Caused by Not Buying from the Experts

Load Cell Cabling & Accessories

The cable connecting your sensor to the transmitter is often the weakest link. Because the output signal is in millivolts (mV), it is highly susceptible to electrical interference. You must use a dedicated load cell cable with proper copper braiding or foil shielding.

The 4-Core vs. 6-Core Rule:

- 4-Core: Suitable for short distances.

- 6-Core: Essential for runs over 10–15 meters. The two extra wires are "sense" lines that monitor the voltage at the load cell and allow the amplifier to compensate for the voltage drop caused by cable resistance.

Need more? Learn more in our blog:

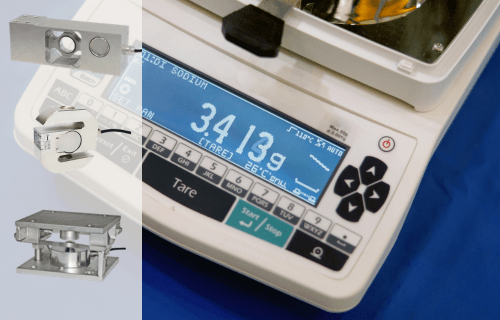

Load Cell Electronics: Signal Conditioning and Displays

A raw load cell signal (mV/V) is too weak and unintelligible for most PLCs or industrial controls. You need electronics to bridge the gap.

Load Cell Amplifiers and Transmitters

These devices convert the millivolt signal into standard industrial outputs like 4-20mA or 0-10V. Modern transmitters, such as the Laumas TLB series, can also directly output to fieldbus protocols, including Ethernet/IP, enabling seamless integration with Allen-Bradley PLCs.

Indicators and Controllers

If you need a local display for an operator, you require an indicator. These range from:

- Basic Readouts: Simple LED displays powered by 230VAC.

- Controllers: Units with built-in relays that can trigger alarms or stop a process when a specific weight setpoint is reached.

- Advanced Units: High-end controllers offering dual displays and complex configuration software for automated batching.

Explore the electronics further:

Explore our range of Load Cell Transmitters, Displays and Accessories here.

Load Cell Electronics: Advanced System Integration

Summing Multiple Load Cells

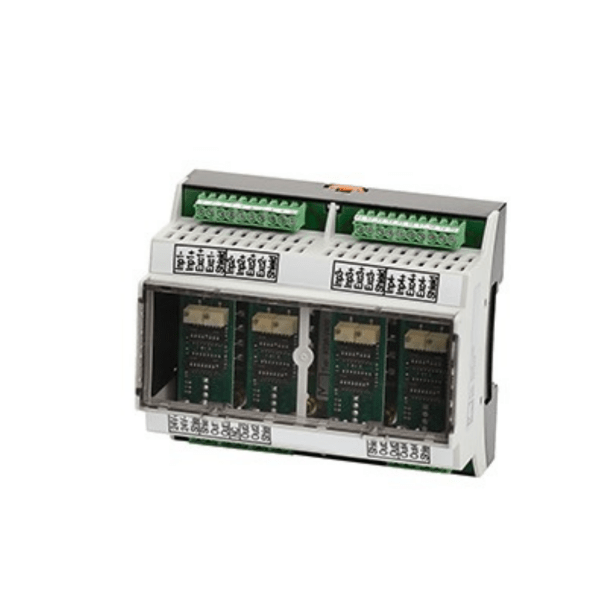

When a tank or platform sits on four legs, you have four separate signals. These must be combined into a single weight reading.

- Analogue Junction Boxes: The traditional method uses potentiometers to adjust the sensitivity of each channel until they match manually.

- Digital Equalisation: Modern transmitters can accept multiple direct inputs (e.g., 4 channels) and digitally sum them, eliminating the need for a separate summing box and manual potentiometer adjustment.

Data Logging and Diagnostics

For testing applications—such as breaking a power pole to test its strength—you need more than a display; you need data logging. High-speed loggers can capture peak forces during destructive testing. For maintenance, handheld load cell testers are invaluable. They allow technicians to view live readings and simulate calibration without needing to lug around heavy test weights.

Get a deeper understanding in our blogs:

Read: Summing or Averaging Load Cell Signals

Read: Load Cells with Data Logging Software

Read: Product Review – TSA HH4-WT-5C Handheld Load Tester

Still need help? Contact us today!

Still need a little help finding the right load cell for the job? the ADM team is here to help! ADM Systems has offices in Brisbane, Melbourne, and Perth, with helpful staff ready to support your next project! Send any questions to the team via our contact page or call them directly on 1300 236 467.