What type of Load Cell should I use?

ADM Instrument Engineering stocks a wide range of load cells and is on hand to offer you expert advice in what type of load cell is best suited to your application.

So, what types of load cell are available and what applications are the different types of load cell best suited to?

Basically a load cell is a device that measures force. Some can measure a compression force, which is a force pushing down onto the device. Others can measure a tension force, which is a force pulling away from the device. Some load cells can measure both compression and tension forces.

Miniature Load Cells

Miniature button load cells measure compression forces only. They are ideal for any application where available space is very limited. The load cell is usually cemented into position because it is too small for any mounting hardware. Typically measuring ranges are available up to a maximum of 500kgs. Possible applications include retrofitting load measurement in machinery that wasn't originally designed to take load cells.

Compression (Button) Load Cells

Standard button load cells are the larger brothers of the miniature button load cells. As with the miniature button load cells they are designed to measure compression only. With the addition of weight module hardware, they are mainly used to weigh tanks and silos. The weight module hardware ensures the forces are correctly applied and prevent the connection being opened. This is particularly important with tall silos, where wind forces on empty silos can cause them to topple.

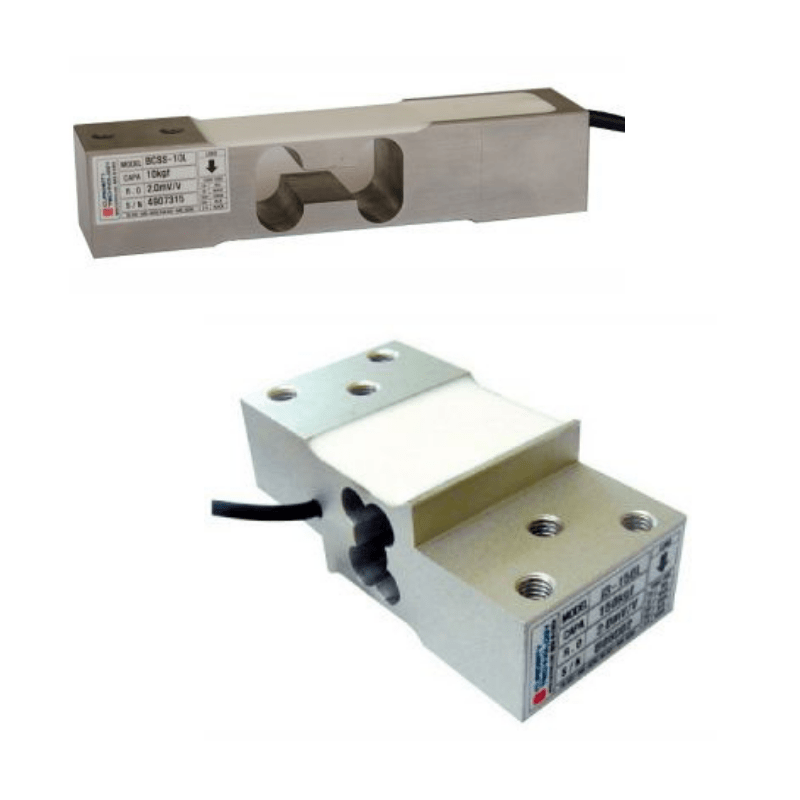

Bending Beam Load Cells

Bending beam type load cells are used in many applications because their compact beam shape makes them easy to fit. They have stainless steel bellows making them impervious to water. For measuring low weights you may want to look at one of the alternative load cells mentioned here, as bending beams can have a slightly reduced accuracy at lower weight ranges.

Tension / Compression Canister Load Cells

This is the type of load cell that is typically found on weigh bridges. They are available in a wide range of physical sizes, with a good choice of measuring ranges. A rocker column-type load cell can be used where alignment of the load will vary. Rocker column load cells have a unique dual radius loading surface. A large radius in the centre, where the load measurement is made and a smaller radius at the outer extremities. This allows the load cell to rock, avoiding serious adverse loads due to the differential expansion of the weighbridge.

Shear Beam Load Cells

Shear beam type load cells are very often used in bulk handling equipment. Applications include filling machinery, industrial floor scales, tank and silo weighing. They make good multi-load cell floor scales, but they should not be exposed to corrosive fluids.

Single Point Load Cells

Single point load cells have an internal parallelogram structure that ensures the internal strain gauge only responds to force in one direction. If the load cell is levelled, it only responds directly to weight and is not affected by any side forces. This makes them perfect for weighing applications, where you find it impossible to control side forces. They are very often used with a small scale base for measuring lower force levels.

S-Beam type load cellss are extremely versatile and measure either compression or tension forces. They are particularly good for weighing heavy objects that are cumbersome to handle. Lowering a bulky object down onto a scale base risks overloading and damage from the load being dropped. Lifting the load with a tension S-Beam in line will give immediate and accurate measurement of weight whilst minimising handling. This solution is also totally self-aligning and gives accurate results. S-Beams require a safety chain when used in crane applications to avoid the risk of an overload failure that could cause a dropped load.

For further information on load cells contact ADM Instrument Engineering.

WAS THIS INFORMATION USEFUL?

Why not share it with you industry peers on LinkedIn? Simply click on the blue LinkedIn share icon below.